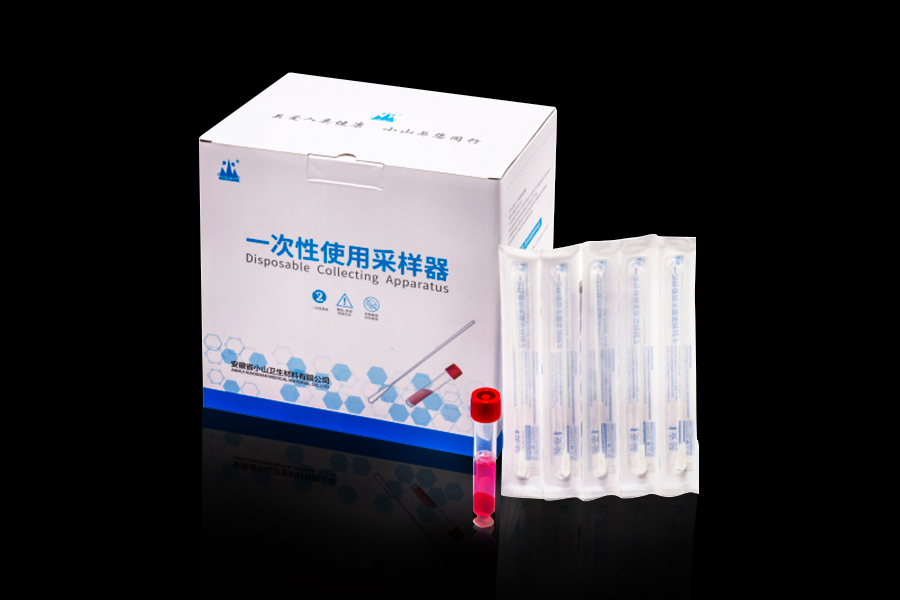

Testing the sealing integrity of a Disposable Sampling Apparatus container is critical to ensure that no leakage occurs during sample transportation, which could compromise sample integrity, pose biological risks, or violate regulatory compliance. Several standard methods are used in the industry to evaluate seal integrity. Here are the most common and effective approaches:

1. Visual Inspection:

This is the most basic level of integrity testing. Each container is checked for visible defects such as cracks, improper sealing, or misaligned closures. Although it is not sufficient on its own, visual inspection is often used as an initial quality control step before more rigorous testing.

2. Dye Penetration Test:

In this method, a dye solution (usually a colored liquid such as methylene blue) is applied to the sealed container. The container is then observed to see if any dye leaks into or out of the sealed area. This test helps detect pinholes, weak seals, or faulty closures.

3. Vacuum Leak Test:

The container is placed in a vacuum chamber and subjected to reduced pressure. If there is any leakage, it is detected by observing bubbles from the container submerged in a fluid or by monitoring pressure changes in the system. This method is effective for detecting very small leaks.

4. Pressure Decay Test:

This non-destructive test involves applying air pressure to a sealed container and then monitoring for pressure loss over time. A drop in pressure indicates a compromised seal. This method is suitable for high-throughput quality control lines.

5. Burst Test:

This test involves increasing the internal pressure of the container until it bursts. The burst pressure is measured and compared to acceptable limits. While destructive, this method helps determine the maximum pressure the seal can withstand during rough transportation.

6. Microbial Ingress Test:

Used mainly in pharmaceutical or clinical applications, this test evaluates whether microorganisms can penetrate the seal under controlled conditions. Containers are exposed to a microbial challenge and then incubated to detect contamination. This test simulates worst-case conditions.

7. Helium Leak Detection (Mass Spectrometry):

This highly sensitive method uses helium gas and a mass spectrometer to detect leaks at the microscopic level. Though expensive and usually reserved for critical applications, it provides highly accurate and reliable results.

Best Practices for Sealing Integrity Testing:

-

Perform integrity testing as part of routine quality control during and after production.

-

Include both destructive and non-destructive methods in validation protocols.

-

Use test methods that are appropriate for the intended storage conditions, such as temperature variations, pressure changes during air freight, or rough handling.

By applying one or more of these methods, manufacturers can ensure that the Disposable Sampling Apparatus containers are reliably sealed, minimizing the risk of leakage and ensuring sample safety during storage and transportation.

English

English 中文简体

中文简体